Gas Meter Itron RF1 is a compact residential gas meter designed to accurately measure volumes of natural gas, LPG and all non-corrosive gases. Several versions and options are available to meet various application requirements. Its design minimizes installation costs and enables future field upgrades.

Application :

The RF1 long-term meterology stability makes it the right choice for demanding, high consumption residential gas markets.

Metrology :

The RF1 gas meter meets strict metrological requirements such as MID, O.I.M.L and EN1359 as wll a different national requirements and standards (such as PTB, DVGW and KVGN).

The RF1 is a combination of proven and reliable gas meter concepts and includes :

- A reciprocating synthetic diaphragm

- Crank-controlled and oscillating slides

- Robust and tight connections between components

- The use of precise, light-weight and noise-free plastic parts

During the preliminary test controls on sonic nozzle test benches, all meters are tested at Qmin, O.2 Qmax and Qmax. In accordance with EC regulations, the maximum permissible error is +/-3% from Qmin to 0.2 Qmax, and +/-1.5% from 0.2 Qmax to Qmax.

Operating Principle :

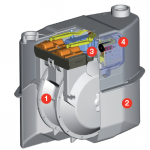

The RF1 is a positive displacement diaphragm gas meter with a stand-alone twin chamber measuring unit.

The twin chambers are each fitted with a flexible and gas-tight diaphragm which is moved by the differential the inlet and outlet pressure. The gas enters one side of the diaphragm plate, and comes out on the other side through a separate port on the valve. When on side is full, the sliding valve moves on to the next position, allowing the gas file the empty side.

A transmission gear and either a magnetic coupling of stuffing box transfer the reciprocating motion to the mechanical or electronical index.

The RF1 meter contains four main parts :

- Measuring Unit :

- Two litre measuring unit

- Plastics selected to facilitate meter recycling (when possible)

- Resistance to chemicals and gas

- High gliding properties to reduce wear on moving parts

- Optimum long-term operation

- A back-run stop prevents the meter from running backwards

- An optional available blackflow flap for 210-250 mm versions protects the meter against the backflow

2. Casing

- High-quality casing material with unique corrosion resistance (aluminium/ zinc-coated sheet steel)

- Additional coating with solvent-free paint

- Also available in a sturdy aluminium casing for high pressure applications up to 1.5 bar (G6 size with 6″ connection distance only)

- Molded connections ensure optimum resistance to corrosion

- Material protected against corrosion (500h salt spray test)

- Available with different connections

- Integrated crimp prevents water residue

- Crimped belt version for PN 0.1, PN 0.2, PN 0.5.

- Safe, DVGW-approved sealing material

3. Transmission

A magnetic coupling (standard) or stuffing box transmits the movement of the measuring unit to the totalizer.

4. Totalizer

Different totalizers are availale depending on the applicaton required :

- “e” series : electric index for a 2-way wired/wireless M-bus communication, with optional electronic temperature correction and optional internal shut-off valve

- “c” series : mechanical index equipped with a Cyble target for retrofitable AMR communication systems. The standarized interface allows you to connect various Cyble communication devices : Pulse, M-bus, or radio frequency wireless links

- “o” series : mechanical index available with a permanent magnet in an index drum. Can be refitted with a low frequency pulse transmitter (Reed Switch)

Technical Specification :

- Gas Type : Natural gas, air, propane butane, nitrogen and all non-corrosive gases

- Cyclic Volume : 2 dm³

- Temperature range

– Gas : -25℃ to +40℃ (-10℃ to +40℃ for G1.6)

– Ambient : -25℃ to +55℃

– Storage : -40℃ to +70℃ - Maximum Operating Pressure : 0.5 bar

- Measuring range :

G1.6 : Qmin (0.016 m³/h) ; Qmax (2.5 m³/h)

G2.5 : Qmin (0.025 m³/h) ; Qmax (4 m³/h)

G4 : Qmin (0.04 m³/h) ; Qmax (6 m³/h)

G6 : Qmin (0.06 m³/h) ; Qmax (10 m³/h) - Casing Material : Aluminium/Zinc-coated sheet metal

- Accuracy : Class 1.5

- Approval : MID (04/22/EC) module B and D

- Totalizer : IP 54

- Connections :

Single or double pipe connections

Different connetions threads are availale (ISO 228-1 and BS746 standards, national)

Special threads available upon request - Colour : Light grey RAL 7035